Auto parts failure defect system

Failure is "an important issue" in the production of the automobile. How we detect the failure portion of the product is the key.

We continue to improve the system to use more accurately, more easily. it is clear trends to visualize the defect at a glance, we propose support measures that can be managed in real time.

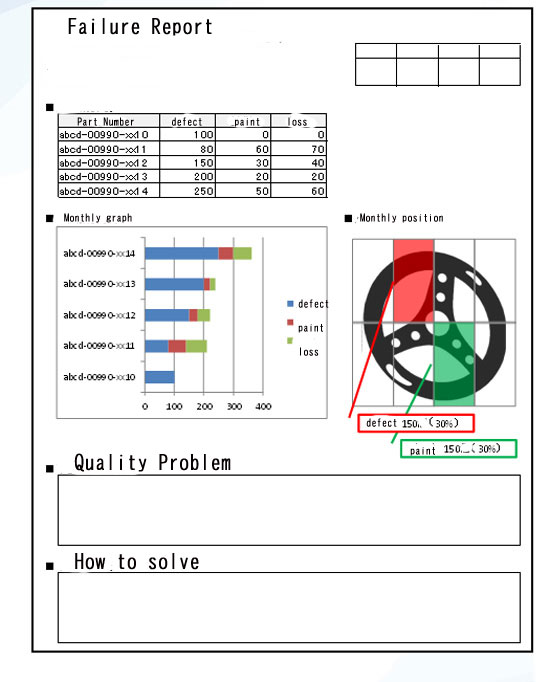

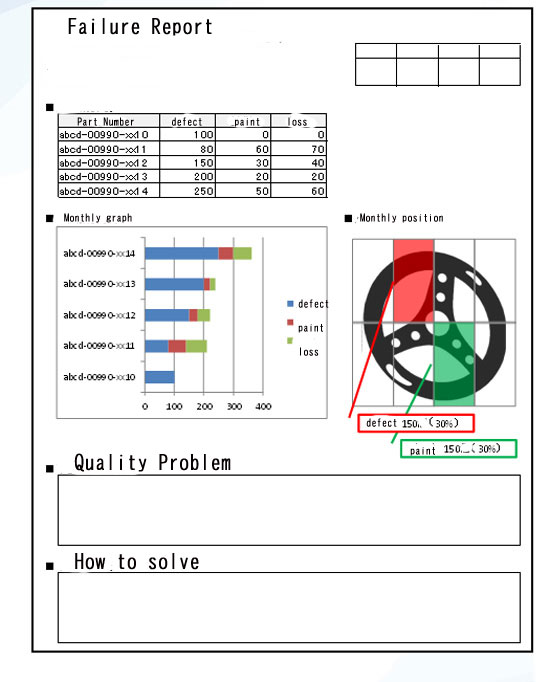

Trend of defect places, you can manage in real time

Input that does not impose a burden on the worker

- Fixed custom frame for iPad

- Stylus input

- Screen configuration without scrolling

Visualization of the defect place using excel

- We can see failure portion with the coordinate

- Graphed image of failure

- The bad positions are shown with color coordinate

- The output is shown in the well known excel sheet

- Quality problem can be determined by the trend graph

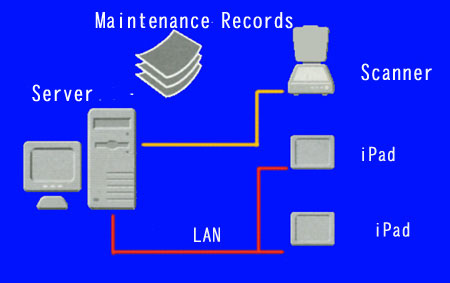

Earthquake proofed underground fortress servers

- Dedicated Server

- Securing leased line

Multilingual

Accommodate model change

- Additional changes to the model

- Additional changes to the product number

Maintenance equipment maintenance system

"Minimize the damage" shortening time-to-repair of the equipment should be kept. Without going back to the office, the parts repair history and preservation of the past are provided with the terminal iPad, we also propose a system that can be arranged in the field Search.

Visualization in repair records using iPad

- Handwritten Scan records are saved

- The repair manual

- Necessary parts for repair

- Cut the time for repairing